Permit to Work (PTW)

Introduction

A Permit to Work (PTW) system is a controlled way of managing high risk activities in a high risk environment. A critical component of this system is the risk assessment process, which helps identify and mitigate potential hazards before work begins, and outlines specific safety precautions that must be followed. This is more than just authorisation – it’s a culture of accountability, risk awareness and collaboration between workers, supervisors and safety officers. The permit process is a structured system for issuing, approving and managing permits, with defined roles and responsibilities to keep things safe. Defining the roles and responsibilities of personnel involved in the PTW process is key to its success.

PTW is critical in maintaining workplace safety, especially in industries like construction, manufacturing, oil and gas and chemical processing.

This guide goes into detail on PTW, including safety culture, benefits, challenges, common misconceptions, real world case studies and technology to make it work.

History of the Permit to Work System

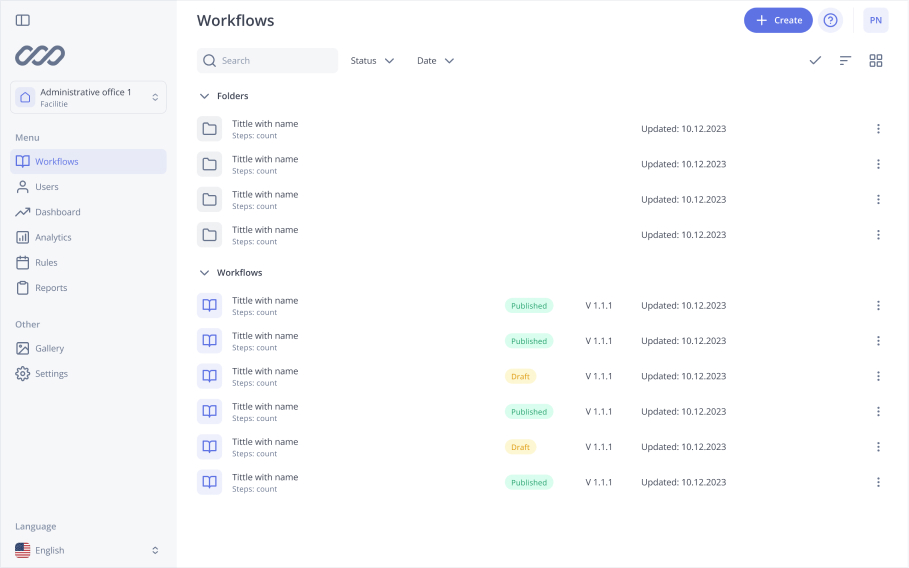

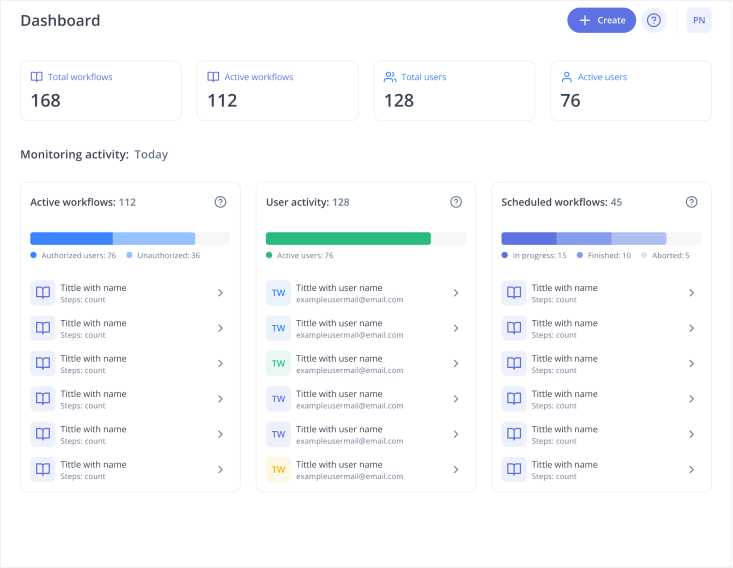

Work permits used to be simple paper checklists to ensure basic safety measures were met. As operations got more complex the PTW framework grew to include hazard analysis, risk assessment and multi level authorisation. Now digital PTW systems powered by automation, real time monitoring and artificial intelligence are changing safety management by offering many advantages over traditional methods. These systems collect valuable data that helps organisations improve their safety practices and manage risk better. An electronic permit system also increases efficiency, enables real-time information sharing, and enhances collaboration for better safety management.

Benefits of PTW

Implementing a PTW system gives you:

- Greater Safety: All hazards identified and mitigated before work starts. Specific safety precautions are outlined to protect workers from accidents and injuries.

- Regulatory Compliance: organisations meet industry safety standards and legal requirements.

- Better Communication: clear and structured communication between teams and contractors.

- Risk Reduction: less chance of workplace accidents and incidents.

- Accountability: roles and responsibilities defined to comply with safety measures.

- Operational Efficiency: work planning streamlined and less unexpected delays.

- Incident Prevention: errors minimised and risks reduced in high risk environments.

- Safety Equipment: investment in better safety equipment to mitigate human error and improve operational procedures.

- Safety Procedures: well documented safety procedures to ensure safe execution of high risk activities.

PTW Challenges

While PTW systems are great, they also come with:

- Administrative Burden: Manual permits can be time consuming and confusing.

- Resistance to Change: Workers and management may not want to adopt new safety protocols.

- Human Error: Incomplete or incorrect permit paperwork can be a big safety risk.

- Tech Integration: Converting from paper to digital PTW requires training and investment.

- Permit Abuse: Unauthorised or improper permit issuance can compromise safety.

- Cost: Implementing and maintaining a robust PTW system costs money.

- Risk Assessment: Skipped risk assessment can lead to increased safety risks and non-compliance. You have to identify and manage the hazards before the work starts.

- Safety Regulations: Compliance with safety regulations is key to minimising risks in high hazard areas and avoiding fines. Standardised procedures, risk assessments and good documentation is key.

Real-World Case Studies: PTW in Action

Case Study 1: Oil Refinery Shutdown Maintenance

An oil refinery was scheduled for a major shutdown for maintenance which included multiple high-risk tasks such as hot work, confined space entry and electrical maintenance. The PTW system ensured hazard identification, multi-level approvals and continuous supervision, especially for confined spaces where specific work permits and safety precautions are critical to manage risks like asphyxiation and toxic atmospheres. The shutdown was completed without any major incidents, thus highlighting the effectiveness of a well-structured PTW system.

Case Study 2: PTW Failure in a Chemical Plant

A chemical plant had a hazardous gas leak due to unauthorized maintenance work. Investigation found out that the PTW system was bypassed and critical safety measures were overlooked. This incident emphasized the importance of strict adherence to PTW protocols and the need for digital tracking systems to prevent unauthorized work.

Common Misconceptions About PTW

Despite its importance, PTW systems are often misunderstood. Here are some common misconceptions:

- “PTW is just a formality.” In reality, PTW is a risk mitigation tool.

- “It delays work progress.” When done efficiently, PTW does not cause unnecessary delay.

- “Only management is responsible for PTW compliance.” Workers also play a big role in following PTW protocols.

- “PTW is only for high-risk industries.” Any workplace with hazardous activities can benefit from a PTW system.

The Future of PTW: Digital Transformation

Industry 4.0 has brought about the rise of digital PTW systems. A cold work permit is vital for safety during non-thermal operations such as chemical cleanups, scaffolding and heavy lifting. Features like real-time tracking, cloud-based documentation and AI-driven risk assessments are making permit to work systems more efficient and reliable than ever before. Organisations adopting digital PTW solutions get:

- Less Human Error through automated workflows.

- Faster Approvals with mobile-enabled apps.

- Better Compliance Tracking with real-time analytics.

- Better Data Management: Digital platforms store historical PTW data for future audits and analysis.

- Remote Access: Cloud-based PTW systems allow real-time monitoring from anywhere.

- AI-Driven Insights: Advanced analytics predict and prevent potential hazards before they happen.

Best Practices for Implementing a PTW System

To get the most out of PTW organisations should:

- Thorough Training: Ensure all employees know the PTW system and why it’s important.

- Regular Audits: Conduct regular inspections to identify gaps in the system.

- Clear Documentation: Keep detailed and accurate records of all work permits issued.

- Technology Adoption: Invest in digital PTW solutions for efficiency.

- Stakeholder Engagement: Get all relevant personnel involved in the PTW process to improve compliance.

- Continuous Improvement: Update and refine PTW procedures based on incident reports and feedback.

- Digital Permit to Work Systems: Use digital PTW systems for safety, to harvest data for risk management and to manage workplace hazards.

Conclusion

A Permit to Work (PTW) is more than a document; it’s a safety tool that protects lives, assets and the environment. By using technology and a strong safety culture you can get the most out of PTW’s, and run safer and more efficient operations. Looking forward to AI and digital systems will make PTW’s even more reliable and efficient and make the workplace safer for everyone. Successful implementation, continuous improvement and innovation is key to better workplace safety. A good PTW system contributes to long term safety, efficiency and success for both employees

Simplify the way people work and learn at the frontline

See the industry-leading how-to platform in a 30-minute live demo.

Learn more