Machine availability is a big deal in manufacturing and industry, it’s a direct factor in productivity, efficiency and profitability. Knowing how to measure, analyze, and improve machine availability helps to minimize idle time and maximize output.

This guide covers the basics of machine availability, definition, calculation, affecting factors, and how to improve it. By using operational data to refine maintenance strategies and reduce unproductive periods, manufacturers can gain valuable insight into machine behavior. They can then take a proactive approach to maintenance strategies and find opportunities for increasing availability.

What is Machine Availability?

Machine availability is the percentage of time a machine is running and ready to run compared to the total scheduled production time. It’s a key component of Overall Equipment Effectiveness (OEE score).

High machine availability reflects a dependable system with few unproductive periods, whereas low availability signals recurring failures and operational inefficiencies.

Machine Availability Calculation

Machine availability is typically calculated using the following formula:

Availability = Actual Operating Time ÷ (Scheduled Time – Planned Downtime) × 100%

Where:

- Actual Operating Time (Equipment Run Time): The actual time the machine is running and producing (availability run time planned).

- Scheduled Time (Planned Production Time): The total time the machine is supposed to be running (maximum time).

- Planned Downtime: Scheduled maintenance, breaks and other pre-planned stops. Note: Planned and unplanned downtime (scheduled maintenance, lunch breaks) is not included in the Scheduled Time before calculating machine availability.

Now that you know the formula, let’s see how it works in practice.

Your factory operates for two days:

| Day | Planned time (hrs) | Planned downtime (hrs) | Unplanned downtime (hrs) | Actual run time (hrs) | Availability (%) |

|---|---|---|---|---|---|

| 1 | 8 | 1 | 1 | 6 | 6 / (8 – 1) × 100% = 6 / 7 × 100% = 85.7% |

| 2 | 8 | 1 | 0 | 7 | 7 / 7 × 100% = 100% |

| Total (2 days) | 16 | 2 | 1 | 13 | 6 + 7 = 13 hours of work out of 14 planned Availability = 13 / 14 × 100% = 92.9% |

This means your machinery is idle 7.1% of your planned production time. Over a full year this is approximately 26 days of lost production — nearly a full month of capacity sitting idle!

Run Time vs Downtime: What Counts and What Doesn’t

Run time is the time the machine was producing. Total downtime is the time it wasn’t producing.

This is easiest to see with a day example:

- A machine started working at 8:00 AM.

- From 8:00 AM to 10:30 AM it produced parts (2.5 hours of run time planned production).

- At 10:30 AM a worn part was noticed and replacement began. The replacement continued until 11:00 AM (0.5 hours of unplanned stops).

- Then it worked again until 12:00 PM (1 hour of run time).

- Lunch was from 12:00 PM to 1:00 PM.

- It worked again from 1:00 PM to 5:00 PM (4 hours of run time).

Total: Run time = 2.5 + 1 + 4 = 7.5 hours. Machine downtime = 0.5 hours. The time planned production was 8 hours (minus lunch).

But remember: not all idle periods are equal. Replacing a part is an unscheduled interruption. You didn’t plan for it. It’s a real loss.

But if you scheduled optimize maintenance strategies at the end of the day for 0.5 hours, that would be planned downtime. It’s subtracted from the planned time before the calculation. The result would be different: 7.5 hours planned (8 minus 0.5 hours for servicing), 7.5 hours actually worked, machine availability = 100%.

Availability vs Utilization: What’s the Difference?

People often confuse machine availability with machine utilization. These are different concepts and this confusion can lead to wrong decisions.

| Criterion | Machine availability | Machine utilization |

|---|---|---|

| Focus | System readiness | Actual system use |

| Question answered | “Is the machine ready to work?” | “Is it being used to its capacity?” |

| Loss source | Maintenance strategies, breakdowns | Idle time, scheduling inefficiency |

| Indicator of | Reliability | Production planning efficiency |

There’s a concept called availability “nines”, when availability is expressed as a number of nines: 99%, 99.9%, 99.99%.

These numbers represent the actual annual downtime:

- 90% availability = 36 days of downtime per year

- 99% availability = 3.6 days of downtime per year

- 99.9% availability = 8.7 hours of downtime per year

- 99.99% availability = 52 minutes of downtime per year

Factors Affecting Machine Availability

Scheduled Maintenance

Maintenance is needed to keep machines running at their best. But excessive maintenance due to unnecessary and inefficient maintenance practices can cause idle time. Maintenance should be planned carefully to balance maintenance needs with production requirements. Effective maintenance programs help reduce machine unproductive time significantly.

Unplanned Downtime

Breakdowns, malfunctions and unexpected failures reduce machine availability and require equipment repair that affects operations. Identify the root causes and implement preventive measures to mitigate these issues. Unplanned maintenance can be very costly especially in industries where equipment failure directly affects revenue streams. Operational pauses happens when manufacturing equipment fails unexpectedly (failure rate).

Changeovers and Setup Time

Frequent production changeovers and long setup times reduce the effective running time of the machine. Reduce changeover time through proper planning and machine availability will increase. Tool breakage during changeovers can lead to many downtime occurrences that impact productive manufacturing time.

Supply Chain Disruptions

Lack of raw materials, spare parts or tools can cause machine idle time and affect machine availability. A well managed supply chain ensures that essential resources are always available when needed.

Operator Efficiency

Human factors such as operator error, training deficiencies and manpower shortages also affect machine availability. Provide adequate training and clear operational guidelines to minimize errors and increase machine uptime. The maintenance team plays a crucial role in ensuring smooth and reliable operations.

Environmental Factors

Extreme temperatures, humidity, dust and other environmental conditions can affect machine performance and quality and lifespan. Proper climate control and protective measures can mitigate these risks.

Aging Equipment

Older machines are more prone to breakdowns and inefficiency. Regular upgrades, refurbishment or replacement can help maintain high machine availability and machine reliability.

How to Increase Machine Availability

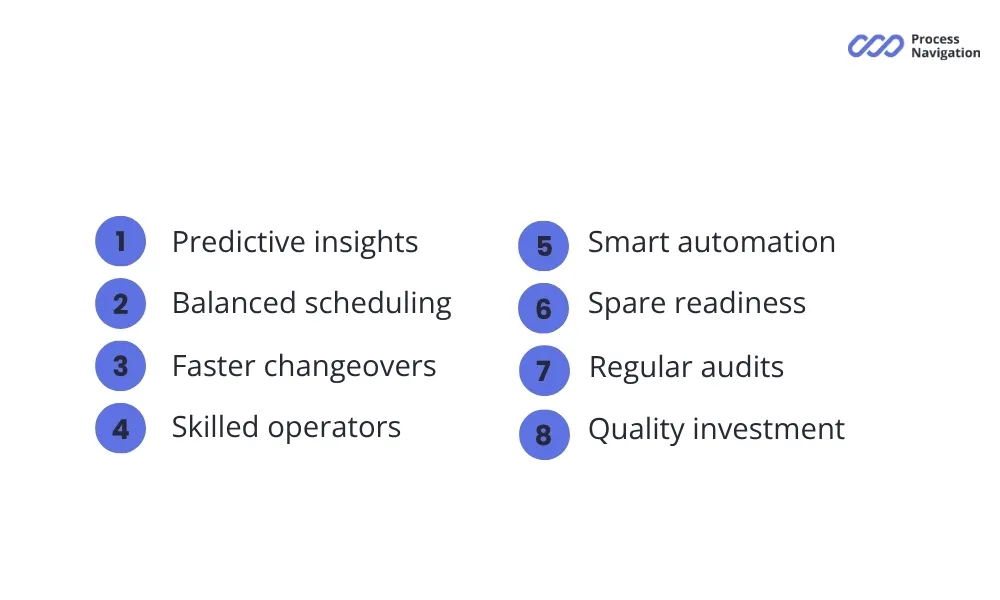

Use Predictive Maintenance. Instead of waiting for a machine to fail, predictive maintenance helps you catch issues before they become serious. By using IoT sensors and data analytics, you can monitor machine performance in real time and address problems early. This helps avoid unscheduled interruptions and keeps processes running efficiently.

Optimize Preventive Maintenance. Routine maintenance is important, but if it’s not scheduled properly, it can either be excessive or insufficient. Finding the right balance ensures that machines get the care they need without unnecessary downtime. Review your operational schedules and adjust them based on real usage data rather than fixed intervals.

Reduce Setup and Changeover Times. Long setup and changeover times reduce workflow efficiency. Implementing lean manufacturing techniques, such as Single-Minute Exchange of Die (SMED), can make transitions faster and smoother. The less time spent switching between tasks, the more efficient your machines will be.

Train Your Operators. A well-trained operator can prevent many problems before they happen. Teaching workers how to properly use and troubleshoot machines reduces the risk of errors and improves response time in case of an issue. When operators know how to handle minor problems, they can prevent unnecessary downtime.

Implement Smart Monitoring and Automation. Automated monitoring platforms provide real-time data on machine performance. This allows businesses to spot inefficiencies, detect early warning signs, and take action before a problem escalates. Smart technology reduces human error and ensures machines are running at optimal performance.

Keep Essential Spare Parts on Hand. Nothing is worse than having a machine break down and realizing you don’t have the right parts to fix it. Keeping a well-managed inventory of critical spare parts can save time and prevent long delays in operations.

Conduct Regular Machine Audits. Performing regular audits helps you identify recurring issues and areas for improvement. By analyzing machine performance and service records, you can make better decisions about repairs, upgrades, and process improvements.

Invest in Quality Equipment. Cheaper machines might save money upfront, but they often lead to more breakdowns and higher long-term costs. Investing in reliable, high-quality machines with good warranties and support services reduces downtime and improves overall productivity.

Machine Availability vs Equipment Availability

Machine availability refers to the uptime of an individual machine, while equipment uptime definition considers the entire production line including supporting systems. Understanding this difference helps businesses develop better service and care strategies for improving efficiency and reducing bottlenecks.

By combining predictive predictive servicing, operator training and smart technology you can increase machine availability, and improve overall productivity in your manufacturing operations.

The Role of Operational Availability (Ao)

Operational Availability (Ao) takes it further — it includes all real world factors such as logistics, service delays and human errors. It shows the true readiness of the workflow readiness not just the technical uptime. Overall availability considers the entire manufacturing process and gives an availability score that reflects real world conditions.

FAQ

At least weekly — ideally daily or in real time. Frequent monitoring allows early intervention and helps identify when downtime occurs unexpectedly.

Yes, indirectly. Low machine availability increases operational costs, which affects pricing and profit margins. A large share of these costs results from inefficient calculate OEE use.

Because they add up. 10 minutes a day = 3 hours a month = 30 hours a year. At $5 per part, that could be thousands of dollars in lost output. Plus minor downtime often indicates a bigger problem in the making.

Never plan for 100%. A realistic range is 90-95%. It’s better to underpromise and overdeliver than vice versa. If your machine availability is below 90% first improve operations then take on orders.

Machine availability describes how long equipment is available for operation while reliability indicates how often it breaks down. A reliable machine rarely breaks down but if repairs take a long time availability may be reduced.

-

Lockout Tagout Procedures (LOTO)

Lockout Tagout Procedures (LOTO)In a manufacturing environment equipment and machinery are hazards, especially during maintenance. Improper operation of...

Technology

-

Machine Availability: The Hidden Number Behind Your Production Profitability

Machine Availability: The Hidden Number Behind Your Production ProfitabilityMachine availability is a big deal in manufacturing and industry, it’s a direct factor in...

Technology

-

MTBF, MTTR, MTTA, MTTF: Incident Metrics

MTBF, MTTR, MTTA, MTTF: Incident MetricsIn today’s digital-first world, product or system failure and downtime can have big consequences—missed deadlines,...

Technology