In today’s manufacturing, competitiveness is all about how the shop floor is managed. Shop floor management has become the foundation for transparency, discipline and efficiency on the shop floor.

SFM comes from lean management and the Toyota Production System. These originated in Japan in the mid 20th century and spread globally as a production management tool.

Definition of Shop Floor Management

Shop Floor Management (SFM) is a system for operationally managing production processes at the workplace (workshop, line or section).

The goal is to ensure transparency, control and continuous improvement of processes through shop floor visual management, regular meetings and management involvement.

Shop floor management is different from traditional management in that it moves the decision making from the office to the production floor where the product is created and all critical processes take place.

The big advantage is that problems are identified and solved as they happen rather than after they have become big deviations from the plan. This speeds up response to changes and quality of decisions.

Key Elements of SFM

Understanding the architecture is key to successful system implementation as trying to implement individual elements without a systemic approach will not deliver the expected results:

| Element | Description | Goal |

| Visual control | Boards, metrics, signals | Transparency of processes |

| Structured meetings | Daily stand-ups | Quick problem solving |

| Standard leader work | Regular routes | Control and support |

| Problem escalation | Cascade of meetings by levels | Timely intervention |

The Architecture of Successful SFM System

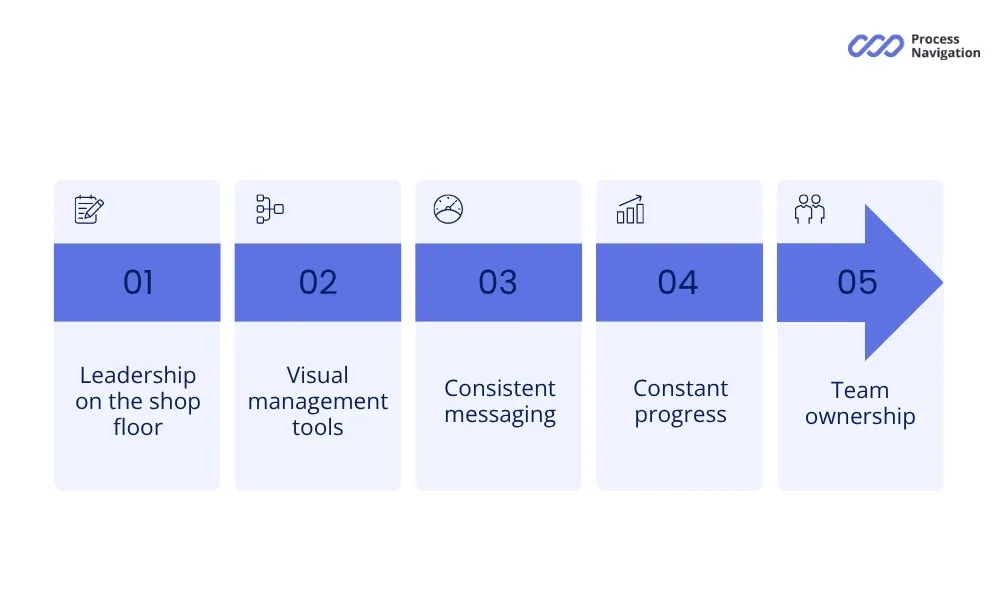

A successful shop floor management system is built on 5 levels. Each level interacts with its neighbors to create a management ecosystem:

| Level | Description |

| 1. Team Level | Daily Management System (DMS) — an operational “day frame” for monitoring goals and activities on the siteShort daily meetings at the shop floor boardTeam led problem solving |

| 2. Supervisor Level | Leader Standard Work (LSW) — regular managerial walks through productionGemba walks — personal presence at the point of value creationReal-time employee coaching |

| 3. Department Level | Tiered huddles — a cascade of meetings from the team to the shop floorSQCDP boards — visual boards for Safety/Quality/Cost/Delivery/PeopleA3 problem solving — a structured solution to complex problems |

| 4. Plant Level | Hoshin Kanri — linking strategic goals with operational managementObeya room — a space for visual management and cross-functional synchronizationKey Performance Indicator Management Production |

| 5. Support Level | Kamishibai audits — card-based standard checksLayered Process Audits (LPA) — multi-level process auditsAndon system — instant deviation signaling system |

Main Goals

Shop floor control delivers measurable business results through a systematic approach:

- Increase Productivity: Productivity increases by eliminating inefficiencies and unnecessary movement through standard operating procedures and better communication.

- Improve Product Quality: Shop floor control ensures quality standards through quality control, regular inspections and immediate response to deviations.

- Reduce Waste: Daily meetings improve efficiency in production processes to reduce material, time and labor waste through better coordination and streamlined workflows.

- Enhance Transparency: Real time data monitoring and open communication helps to identify and fix issues early.

- Engage Employees: Active involvement gives employees ownership and job satisfaction through recognizing their improvement contributions.

Shop Floor Visual Management

Shop Floor Management Board

A core component of visual management, the board acts as the hub for daily team coordination and performance tracking. When thoughtfully designed, it reflects the pulse of production — showing current status, future goals, and the challenges being addressed along the way.

Shop floor management board includes:

- Safety metrics: incident free days, near miss events

- Quality: % defects, number of complaints, FTQ (First Time Quality)

- Cost: performance indicators, cost overruns

- Delivery: plan fulfillment, shipments

- People: attendance, training, improvement suggestions.

OEE Dashboard

Overall Equipment Effectiveness is one of the most important metrics for shopfloor manufacturing, encompassing equipment utilization. The OEE dashboard should be understood by every employee, from operator to plant manager.

Operational visualization of three key metrics:

- Availability: planned vs actual time

- Performance: actual vs ideal pace

- Quality: % of quality products

Example of OEE calculation:

-

Shift Start

-

Shift End

-

Planned Downtime

-

Unplanned Downtime

-

Total Parts Produced

-

Ideal Cycle Time

-

Total Scrap

-

OEE

-

Capacity

-

Total Produced

-

Performance

-

Quality

-

Availability

OEE = Availability × Performance × Quality

OEE = 85% × 92% × 98% = 76.6%

This shows that even with good individual metrics (all above 85%) overall shop floor efficiency can be much lower, that’s why shop floor control focuses on systemic improvement approaches.

Shop Floor Manufacturing: Operational Excellence

Shop floor manufacturing focuses on optimizing production processes through lean principles applied on site. The key idea is to create a stable, predictable value stream through two fundamental principles:

Takt Time — Synchronization with Customer Needs

Takt time sets the rhythm for the entire production system, subordinating all processes to real market needs:

Takt Time = Available Working Time / Customer Demand

Example:

With a 480 minute shift and a requirement of 120 units of production: Takt Time = 480 min / 120 units = 4 minutes per unit

Heijunka — Production Leveling

Heijunka (leveling) solves demand and production process variability. Without leveling shop floor production operates in roller-coaster mode with alternating downtime and rush jobs.

Heijunka reduces variability by:

- Leveling production volumes

- Mixing product lines

- Stabilizing equipment utilization

The following table clearly shows the results of heijunka implementation:

| Without Heijunka | With Heijunka |

| Peak loads | Uniform loading |

| High reserves | Optimal reserves |

| System stress | Steady flow |

Shop Floor Efficiency through PDCA

Shop floor efficiency is achieved through systematic application of the PDCA cycle — operational logic for continuous improvement that should become second nature for every production participant.

PDCA Cycle Implementation:

- Plan: Identify the problem, set the goal

- Do: Implement the action plan

- Check: Measure the results

- Act: Standardize the improvements

Practical PDCA example:

- Problem: High defect rate on assembly line (8%)

- Plan: Goal — reduce to 3%; Hypothesis — inaccurate equipment setup

- Do: Implement daily calibration + train operators in standard setup

- Check: Measure defect rate after one week (result: 4%)

- Act: Standardize new procedure + amend work instructions

This shows that improvement continues through standardization even when production targets aren’t fully achieved, preparing for the next improvement cycle.

Seminar Shop Floor Management: Training Implementation

Shop floor management seminars and shop floor management training are key implementation elements. Experience shows that companies that don’t invest in training spend more resources on error correction and reimplementation.

Shop Floor Management Seminar

These seminars enable executives and line managers to master:

- SFM basics

- visual management

- Gemba walks and Leader Standard Work practices.

Shop Floor Management Schulung

These training programs are presented in a German format, with an emphasis on practical application:

- working with whiteboards

- conducting cascading meetings (tiered huddles)

- applying the PDCA cycle.

How to Implement Effective Shop Floor Management

Step 1: Leadership on the Shop Floor

To implement SFM effectively leadership needs to focus on production. This means direct interaction with employees on the production floor and the ability to solve problems in real time while monitoring current resource status. And prioritize overall equipment effectiveness to improve productivity and performance.

Best practices:

- Do Gemba walk-throughs regularly.

- Engage employees to understand problems and get ideas for improvement.

- On-site coaching for teams.

Step 2: Visual Management Tools

Visual tools are the key to SFM, part of the five pillars that give real-time visibility into performance and issues.

Tools to use:

- Shop Floor Boards: This tool displays KPI’s, targets and faults in one place.

- Andon systems: Instantly show problems for quick fixes.

- Digital dashboards: Real-time updates and access to the whole facility.

- Visual management tools: Quickly communicate information, optimize layout and material flow, improve lean organization and collaboration.

Step 3: Standardized Communication

Shop floor management means a structured communication strategy that prevents miscommunication and ensures everyone is on the same page.

Implementation tips:

- Daily shift meetings under 15 minutes.

- Meeting agendas to keep focus on specific actions.

Step 4: Continuous Improvement

Use proven methods to find and eliminate inefficiencies:

- Focus on “value creation” by looking at areas where processes and actions lead to productivity and efficiency.

- Use clear communication channels to enhance collaboration and transparency, which reduces misunderstandings and improves overall productivity.

- Toyota Production System tips to drive continuous improvement.

- SFM uses tools like root cause analysis and PDCA cycles.

Step 5: Employee Empowerment

Employees are the core of shop floor management and using specialized software can help them even more. Understanding the process and involving employees in decision making will give them commitment and innovation.

How to empower employees:

- Training on lean tools and methods.

- Recognize contributions to improvement.

- Create and maintain cross functional teams.

Measuring Shop Floor Management Effectiveness

Comprehensive measurement system tracks multiple dimensions of shop floor efficiency:

| KPI | Goal | Measurement |

| Lead Time | Cycle shortening | Days/hours |

| First Pass Yield | Quality the first time | % |

| Employee Engagement | Personnel involvement | Index 1-10 |

| Problem Resolution Time | Problem-solving speed | Hours |

| Suggestion Implementation Rate | Proposal implementation | % |

Organizations progress through defined maturity levels, with shop floor efficiency improving systematically:

| Level | Characteristics | Typical results |

| Chaos | No system, reactive management | OEE < 60% |

| Basic | Daily meetings, basic boards | OEE 60-70% |

| Systemic | Structured processes, meeting cascade | OEE 70-80% |

| Optimized | Improvement culture, proactive management | OEE 80-85% |

| World class | Self-managed teams, innovation | OEE > 85% |

Digital Integration: Modern Shop Floor Management

Modern shop floor management integrates with digital solutions:

- MES systems: Real-time production data, automatic OEE collection.

- IoT sensors: Equipment monitoring, predictive analytics.

- Connected Worker Platforms: Mobile access to shop floor processes, real-time process monitoring, and instant escalation.

FAQ

Most organizations see initial results within 3-4 months, with full ROI typically achieved within 12-18 months. Early wins include improved communication and problem visibility, followed by measurable productivity gains.

In highly automated facilities, SFM focuses on equipment effectiveness, predictive maintenance and human-machine interface optimization. Visual management shifts to digital dashboards while maintaining the same principles of transparency and rapid response.

In highly automated facilities, SFM focuses on equipment effectiveness, predictive maintenance and human-machine interface optimization. Visual management shifts to digital dashboards while maintaining the same principles of transparency and rapid response.

SFM is based on the PDCA cycle, A3 problem solving and Hoshin Kanri, which ensures continuous process improvement.

-

Maintenance Plan: What Is It And How Does It Work

Maintenance Plan: What Is It And How Does It WorkIn modern manufacturing, equipment downtime costs businesses thousands of dollars an hour. The difference between...

Technology

-

Competency Management

Competency ManagementModern businesses face a big challenge: how do you ensure every employee has the skills...

Technology

-

Unlocking the Benefits of Total Quality Management

Unlocking the Benefits of Total Quality ManagementIn today’s competitive world, the quality of products and services is becoming the key to...

Technology