Brief Guide: Manufacturing Work Instructions

In today’s fast moving manufacturing world accuracy, consistency and efficiency is everything. One of the best way to achieve this throughout the production process is by using well written work instructions. Creating manufacturing work instructions for manufacturing means creating structured and easy to follow manuals that guide operators through their tasks and improve communication and workflow management.

What are Work Instructions for Manufacturing?

Manufacturing work instructions for manufacturing are a set of instructions that give workers step by step procedures to follow for specific tasks within the production process. These tasks may be assembling components, packaging products, quality checks or shipping finished products. The purpose of these instructions for manufacturing processes is to ensure the end product meets specifications and to help workers do their job better.

In mass production work instructions for manufacturing are key to keeping the production line organized and consistent. They detail every step from sequence of operations to materials required at each stage. This means workers can follow the plan. And a defined and detailed list of materials required for each task helps workers do their job better.

Work instructions are also important during product changes or when moving from one model to another. They reduce changeover risks by ensuring consistency across all production participants and minimizes errors. Errors during production can lead to customer satisfaction problems such as delays, defects, or products that fail to meet customer expectations. By ensuring quality and reliability at every stage of production work instructions maintain customer trust and loyalty.

Work Instructions for Manufacturing: Benefits

Work instructions for manufacturing have many benefits that can improve productivity and product quality. Here are some of them:

- Time and Efficiency: Well written manufacturing work instructions means workers can do their job faster and better. They don’t have to spend time trying to figure out what to do next or looking for instructions. With clear guidance and detailed instructions processes run smoother and quicker.

- Knowledge Sharing: Knowledge sharing is part of the work environment. New employees or those unfamiliar with specific tasks can learn quickly by using work instructions. This also means critical knowledge isn’t lost when experienced employees leave or are re-deployed.

- Defect Elimination and Quality Control: By defining the steps and standards at each stage of manufacturing work instructions reduce defects and production errors. Workers are less likely to make mistakes because they know what the quality expectations and requirements are.

- Safety: Work instructions often include safety protocols and guidelines so workers are aware of the hazards and necessary precautions. By reducing safety incidents manufacturers can improve safety in the workplace.

- Process Standardization: Manufacturing work instructions help to standardize the way tasks are done which is especially important when working with complex production lines. Standardization means every unit of product produced meets the same specifications and quality standards.

And continuous improvement is key for manufacturers to improve productivity, efficiency and quality control in a changing world.

Work Instructions for Manufacturing: Examples

Let’s see how manufacturing work instructions for manufacturing are used in manufacturing:

- Product Assembly Instructions: These instructions will include steps such as description of kit parts, sequence and method of assembly and tips.

- Packaging and Labelling Instructions: In industries like pharmaceuticals or food production packaging and labelling must follow strict guidelines to ensure product safety and compliance. Work instructions in these areas will include step by step instructions on how to pack items, apply the right labels and ensure the packaging is secure for shipping. These instructions are critical to ship products safely.

- Quality Control Checks: In any production process quality control is part of keeping high standards. Work instructions in this area will include instructions for visual inspection, measuring product dimensions or testing products. These instructions will detect defects early and fix them before they reach the customer.

- Maintenance and Repair Procedures: If a piece of equipment on the production line breaks workers will refer to maintenance work instructions. These will include troubleshooting steps, instructions to replace parts or how to clean and lubricate the machinery. Well written work instructions for manufacturing means repairs are done faster and better, less downtime.

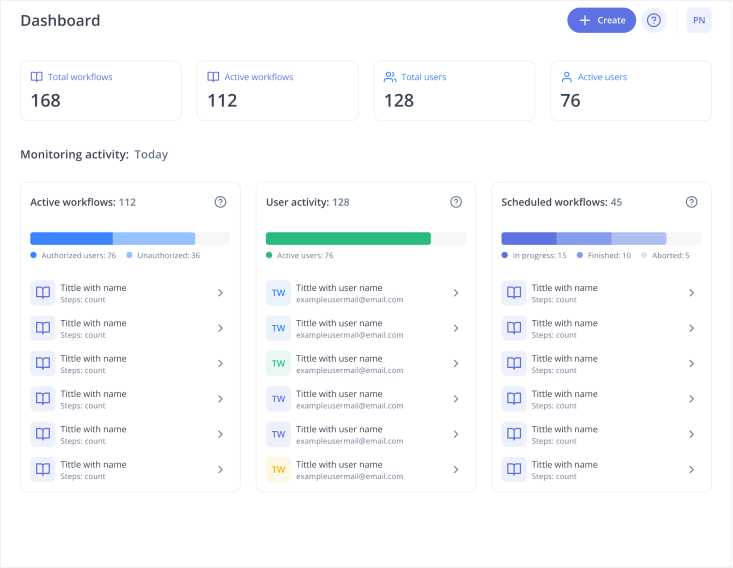

Adding digital work instructions to your manufacturing operations will improve efficiency, safety and process optimization.

How to Create Digital Work Instructions for Manufacturing

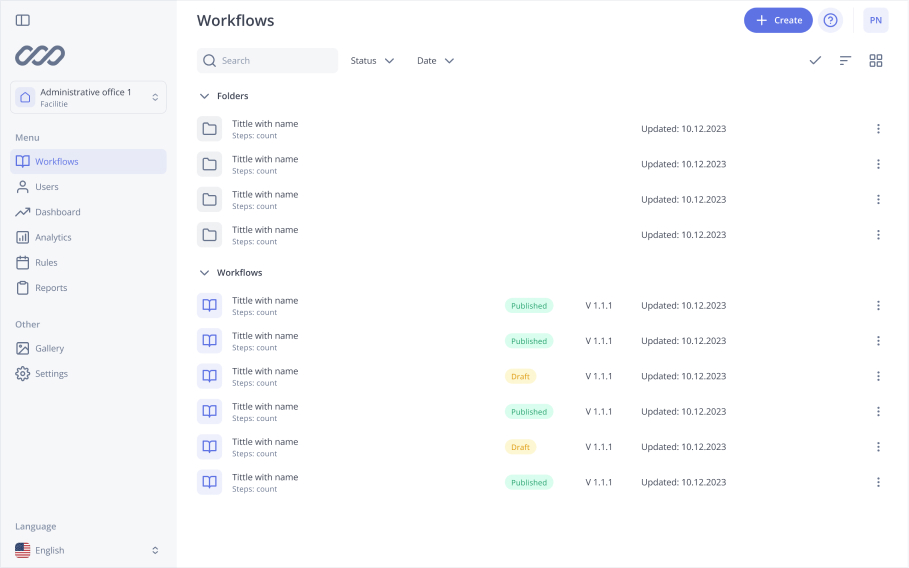

Creating good manufacturing work instructions for production involves several steps. Manufacturing work instructions can be created from scratch but it’s often helpful to use templates or digital tools to make the process easier.

Digital work instructions that can be accessed on computers, tablets or other wearable devices are the best. They allow workers to access updated instructions in real time wherever they are in the manufacturing process.

Here are the steps:

- Step 1: Write a clear title.

- Step 2: Provide a detailed introduction.

- Step 3: Define the task purpose.

- Step 4: Describe the task steps.

- Step 5: Check your information.

Conclusion

Digital work instructions for manufacturing are the new standard in today’s manufacturing world, real time updates, simplicity and collaboration. Follow the above steps and you will create clear and concise manufacturing work instructions to increase productivity, reduce errors and keep high standards throughout your manufacturing process. Modernising your manufacturing with digital solutions will not only increase productivity but also consistency, quality and safety. Many companies still use paper instructions, switching to digital will improve quality control and efficiency.

Simplify the way people work and learn at the frontline

See the industry-leading how-to platform in a 30-minute live demo.

Learn more